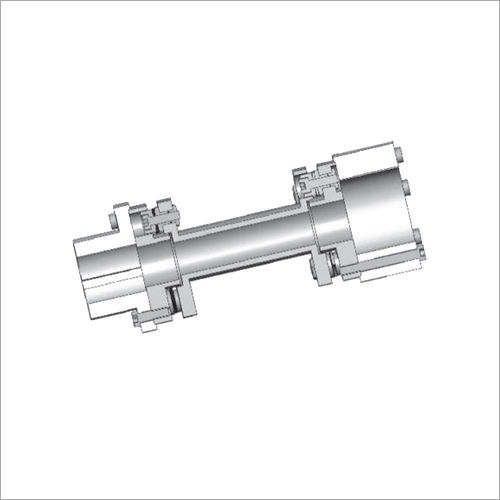

Flexible Shaft Couplings

Price 10.0 INR/ Number

MOQ : 1 Number

Flexible Shaft Couplings Specification

- Max. Speed

- 5000 RPM RPM

- Sealing

- None

- Torque

- Up to 15 Nm N-m

- Bore

- Customizable depending on shaft diameter

- Thread

- Depends on connection type (e.g. clamp or screws)

- Material

- Aluminum Alloy

- Structure

- Two-piece coupling with intermediary rubber block

- Standard

- ISO compliant

- Application

- Torque transmission between shafts

- Surface Treatment

- Other

- Technique

- Precision machining

Flexible Shaft Couplings Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

About Flexible Shaft Couplings

Discover the crowning innovation in torque transmission with our newly released Flexible Shaft Couplings. Crafted from magnificent aluminum alloy and treated with a premium anodized finish, these couplings are engineered for supreme value and reliability. Now available at a competitive price cut, our couplings support up to 15 Nm torque, feature a clamp or set screw connection, and are customizable to your shafts exact diameter. Designed without sealing for efficient performance, each coupling benefits from precision machining for a terrific fit. Proudly ISO compliant and available from leading manufacturers, suppliers, and traders in India.

Outstanding Features and Versatile Applications

Flexible Shaft Couplings offer a combination of value and versatility. They feature a cylindrical structure with a central rubber block, anodized surface for corrosion resistance, and customizable bore sizes. Ideal for applications demanding precise torque transmission between shafts, these couplings are suitable for industrial machinery, automation systems, and robotics. Their flexible connection accommodates minor misalignments, making them the perfect fit for a range of sectors, from manufacturing to assembly lines.

Export Market Reach and Reliable Supply Network

Our Flexible Shaft Couplings are supplied globally, with main export markets including North America, Europe, and Asia. Backed by robust logistics and efficient transport services, we ensure stock ready for dispatch and reliable delivery. Our high supply capability meets both low and high-volume orders. Sample policies are flexible, catering to clients who wish to test product suitability before bulk purchase. Trust our seamless logistics for timely distribution and strong after-sales support.

Outstanding Features and Versatile Applications

Flexible Shaft Couplings offer a combination of value and versatility. They feature a cylindrical structure with a central rubber block, anodized surface for corrosion resistance, and customizable bore sizes. Ideal for applications demanding precise torque transmission between shafts, these couplings are suitable for industrial machinery, automation systems, and robotics. Their flexible connection accommodates minor misalignments, making them the perfect fit for a range of sectors, from manufacturing to assembly lines.

Export Market Reach and Reliable Supply Network

Our Flexible Shaft Couplings are supplied globally, with main export markets including North America, Europe, and Asia. Backed by robust logistics and efficient transport services, we ensure stock ready for dispatch and reliable delivery. Our high supply capability meets both low and high-volume orders. Sample policies are flexible, catering to clients who wish to test product suitability before bulk purchase. Trust our seamless logistics for timely distribution and strong after-sales support.

FAQs of Flexible Shaft Couplings:

Q: How does the flexible coupling ensure torque transmission between shafts?

A: The flexible shaft coupling uses a two-piece design with an intermediary rubber block that accommodates minor misalignments and transmits up to 15 Nm of torque efficiently between connected shafts.Q: What are the main benefits of choosing an anodized aluminum alloy flexible coupling?

A: Anodized aluminum alloy offers excellent corrosion resistance, light weight, and durability, ensuring a long service life while maintaining reliable performance under various industrial conditions.Q: Where can these flexible shaft couplings be used?

A: These couplings are ideal for industrial settings such as automation systems, robotics, machinery assembly lines, and any application where precise torque transmission and shaft alignment flexibility are needed.Q: What customization options are available for shaft diameter and bore size?

A: Flexible couplings can be tailored to exactly match the required inner and outer diameters, based on your shaft specifications, providing a perfect fit and optimal performance.Q: How is the precision machining process beneficial for users?

A: Precision machining assures tight tolerances and a smooth finish, resulting in improved alignment, reduced wear, and extended coupling lifespan, ultimately enhancing user satisfaction and equipment safety.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Couplings Category

Clutch Coupling

Price 2700 INR / Piece

Minimum Order Quantity : 1 Piece

Technique : Other, Machined

Surface Treatment : Other, Polished

Shape : Round

Material : Other, Cast Iron, Steel, or Alloy

Coupling Nut Bolt

Price 150.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Technique : Other, Forging

Surface Treatment : Galvanized

Shape : Cylindrical, Other

Material : Steel

Disc O Flex Spacer Couplings

Price 2500 INR / Piece

Minimum Order Quantity : 5 Pieces

Technique : Forged

Surface Treatment : Galvanized

Shape : Equal

Material : Metal

HRC Coupling

Price 8500 INR / Piece

Minimum Order Quantity : 5 Pieces

Technique : Forged

Surface Treatment : Powder Coated

Shape : Round

Material : Metal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry